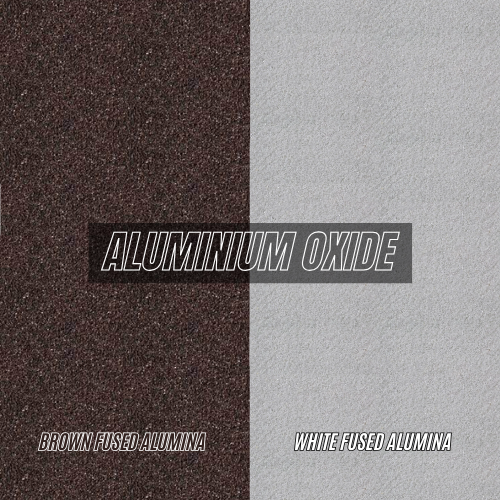

Description

BLASTING APPLICATIONS

- Etching medical and dental parts

- Prepping surfaces for high performance coatings

- Engine heads, valves and pistons

- Cleaning turbine blades

- Surface preparation for metalizing and welding

- Preparation for bonding

CHARACTERISTICS

- Angular, Sharp

- Rapid cleaning rate

- Very hard, approximately 9.0 Mohs

- Bulk density of approximately 1.60 g/cm3

- Relatively low/zero iron content

GRIT SIZES AVAILABLE

We offer Aluminium Oxide blasting abrasive in standard grit sizes or specially sized mixtures of grain sizes to meet just about any surface preparation and finishing requirement including.

| GRIT NO. | F20 | F36 | F40 | F60 | F80 | F100 | F120 | F180 |

| MICRON | 841 – 1190 | 420 – 595 | 297 – 420 | 210 – 297 | 149 – 210 | 105 – 149 | 88 – 125 | 53 – 88 |